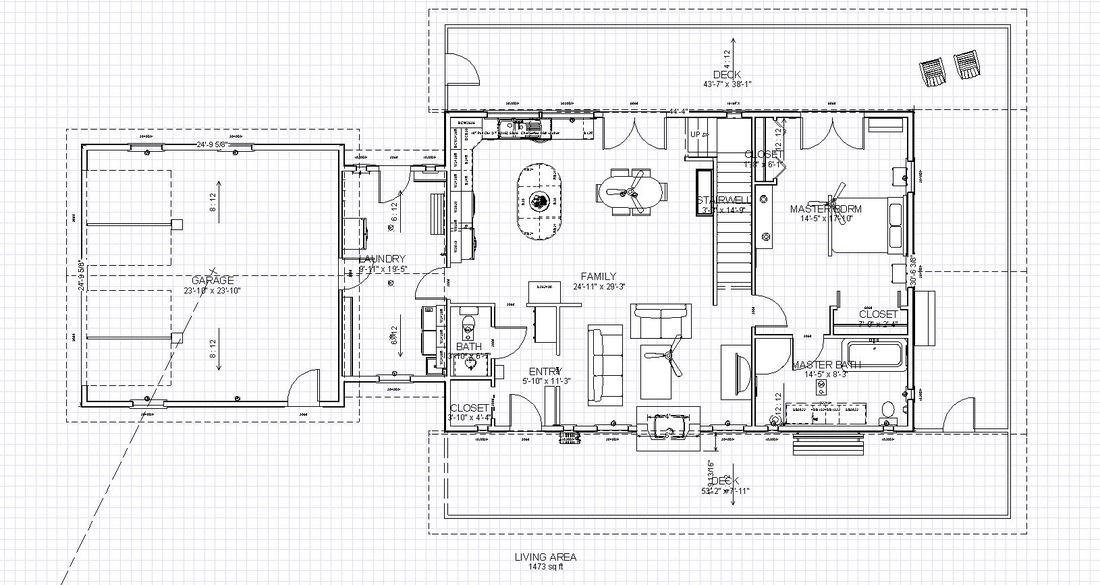

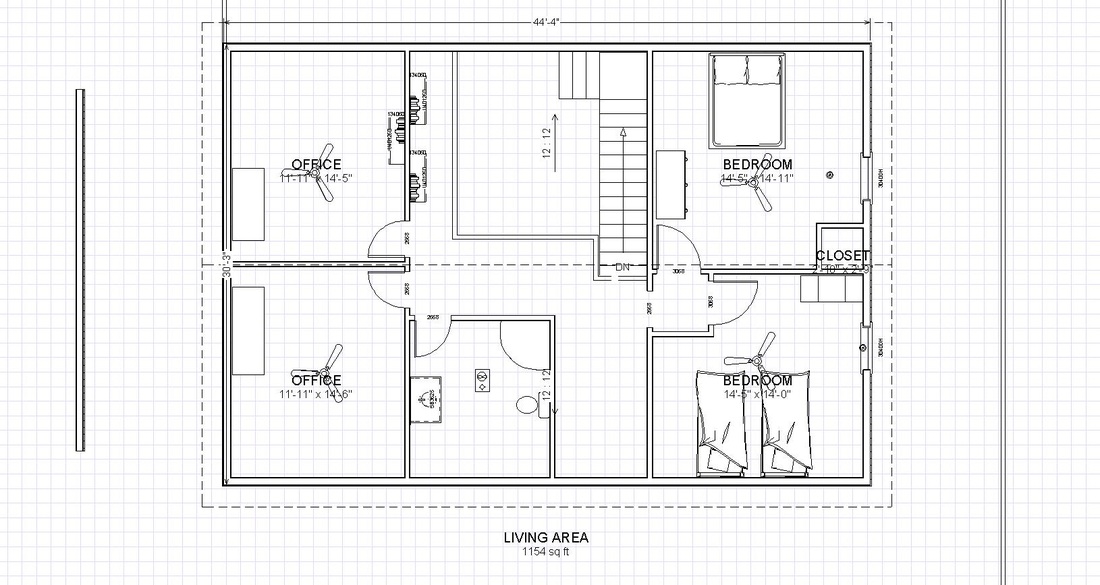

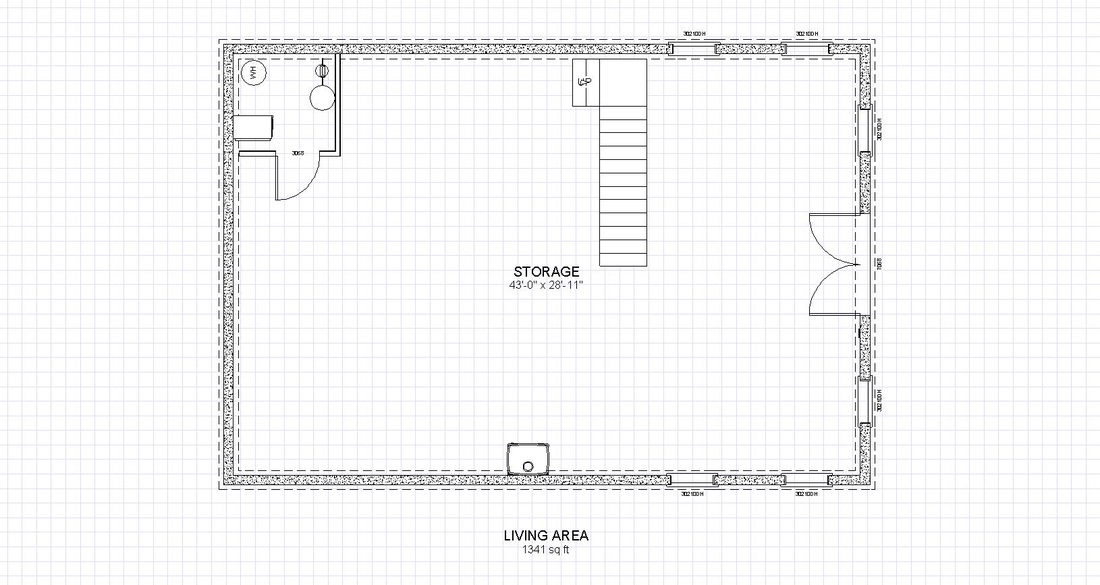

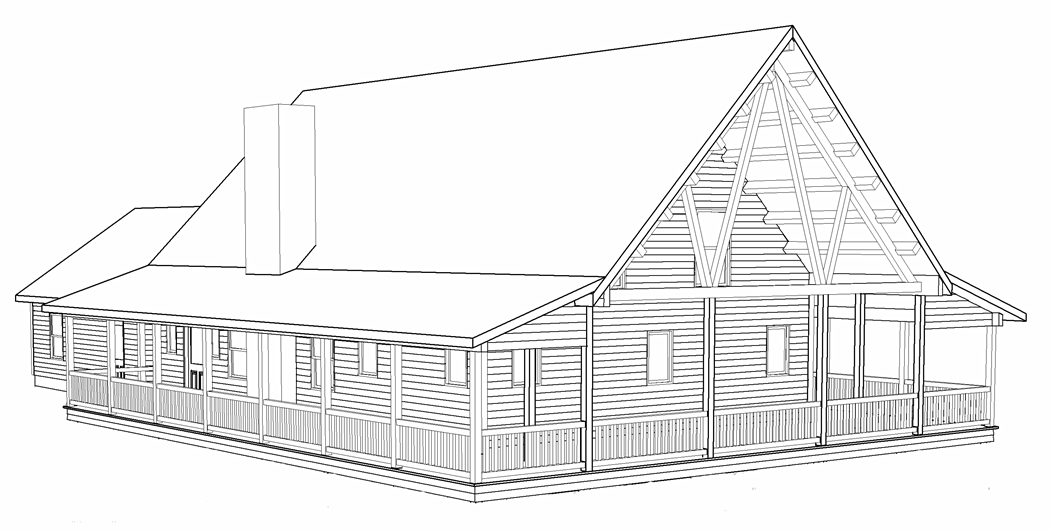

Here's a rendering of our design from 2014 (visit our gallery pages to see how our design tools and skills have evolved!). We had a basic layout that we liked (we started with the Hamilton model) and started adding the features that a) we wanted and b) we needed. The house grew to the floor plan you see below. With this much detail we're able to clearly communicate with our builder and the mill. The mill generated construction drawings (part of the log home package) which will feed directly into the 'house line'. The 'house line' is the state of the art computerized milling, drilling, shaping and cutting machine. This is where northern white cedar logs are transformed into solid cedar home components. Each piece of lumber is processed, bar-coded and labelled so that there's no question of where that piece of wood belongs in our home. Every log in our home is created to exact specifications in a sequence that will allow our builder to open a pack of logs and have access to the pieces in the order that they need to be placed in the home. Each piece is cross-referenced on a packing list, a stacking diagram which highlights areas of the home as well as in the detailed construction drawings. It's very cool! We strongly recommend making trip to tour the mill. Contact us and we can arrange your tour.